Hardware GENERAL INFORMATION

Technical Resources

CERTEX USA provides abundant resources for rigging hardware.

Warnings and Application Instructions

WRONG

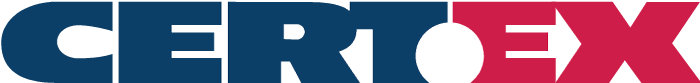

Figure 1

WRONG

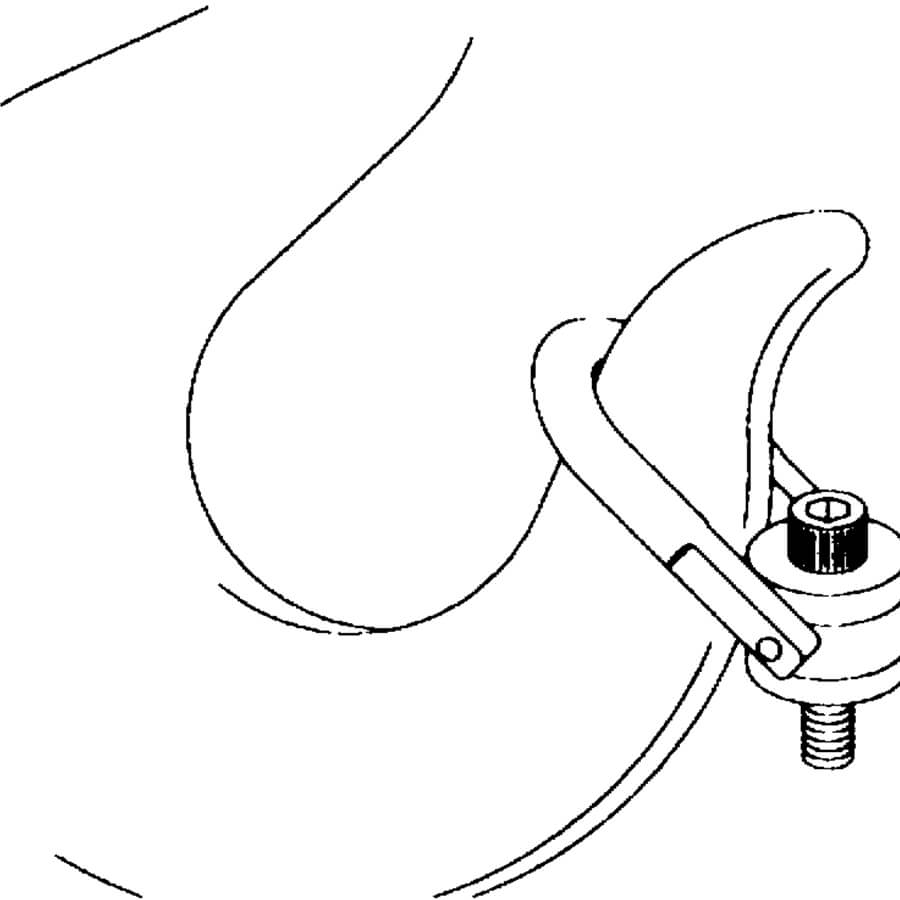

Figure 2

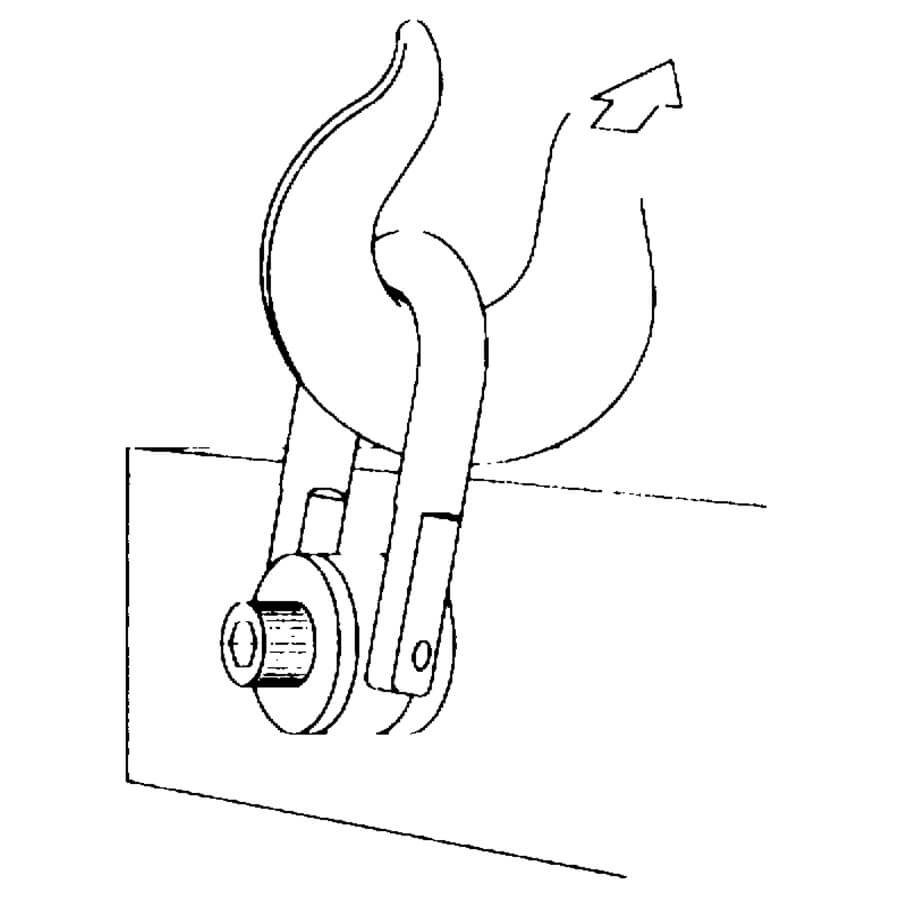

Figure 3

RIGHT

Figure 4

Warnings and Application Instructions

- Use swivel hoist ring only with ferrous metal (steel, iron) or soft metal (i.e., aluminum) loads (work piece).

Do not leave threaded end of hoist ring in aluminum loads for long time periods due to corrosion. - After determining the loads on each hoist ring, select the proper size hoist ring using the Working Load Limit ratings in Table 1 for UNC threads and Table 2 for Metric threads.

- Drill and tap the work piece to the correct size to a minimum depth of one-half the threaded shank

diameter plus the threaded shank length. See rated load limit and bolt torque requirements imprinted on top of the swivel trunnion. (See Table 1 and/or Table 2) - Install hoist ring to recommended torque with a torque wrench making sure the bushing flange meets the load (work piece) surface.

- Never use spacers between bushing flange and mounting surface.

- Always select proper load rated lifting device for use with Swivel Hoist Ring.

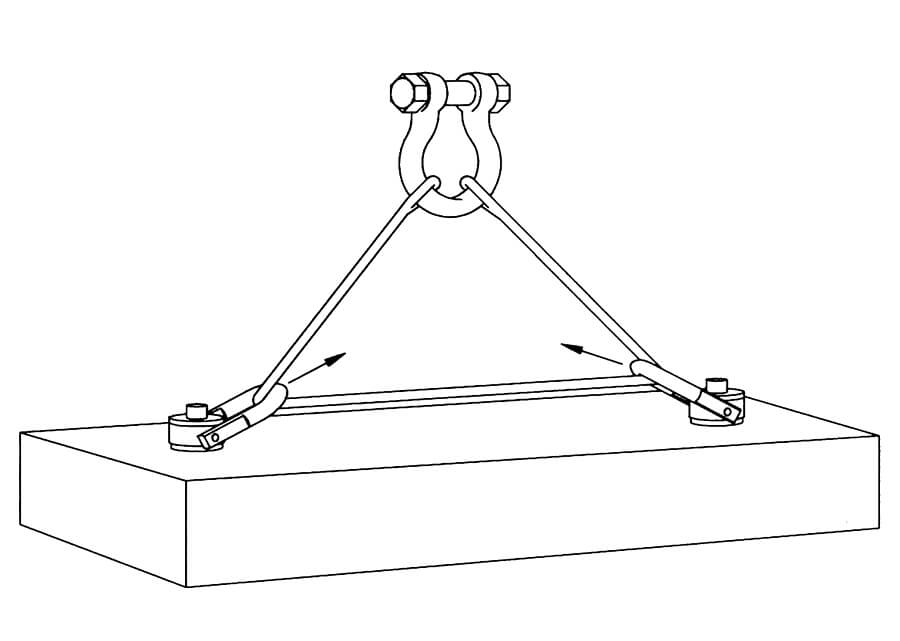

- Attach lifting device ensuring free fit to hoist ring bail (lifting ring). (Fig. 1)

- Apply partial load and check proper rotation and alignment. There should be no interference between load (work piece) and hoist ring bail. (Fig. 2)

- Special Note: When a Hoist Ring is installed with a retention nut, the nut must have full thread

engagement and must meet one of the following standards to develop the Working Load Limit (WLL).

1. ASTM A-563 (A) Grade D Hex Thick (B) Grade DH Standard Hex

2. SAE Grade 8 — Standard Hex

Hoist Ring Inspection/Maintenance

- Always inspect hoist ring before use.

- Regularly inspect hoist ring parts. (Fig. 3)

- Never use hoist ring that show signs of corrosion, wear or damage.

- Never use hoist ring if bail is bent or elongated.

- Always be sure threads on shank and receiving holes are clean, not damaged, and fit properly.

- Always check with torque wrench before using an already installed hoist ring.

- Always make sure there are no spacers (washers) used between bushing flange and the mounting surface. Remove any spacers (washers) and retorque before use.

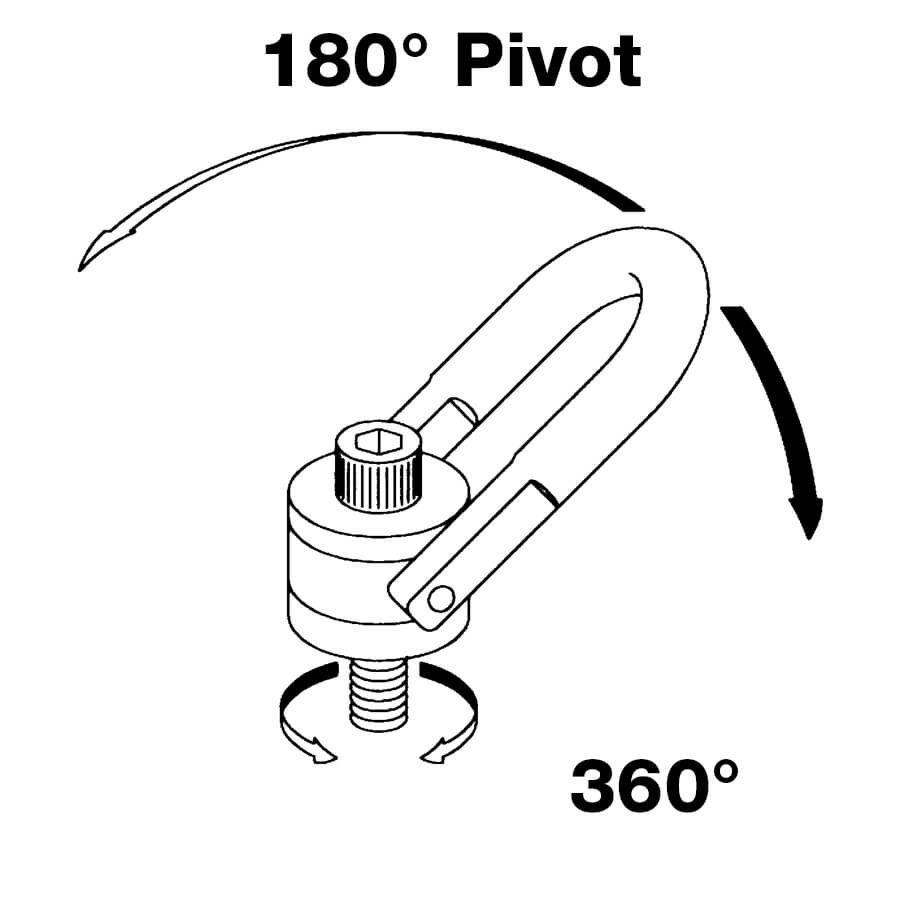

- Always ensure free movement of bail. The bail should pivot 180° and swivel 360°. (Fig. 4)

- Always be sure total work piece surface is in contact with hoist ring bushing mating surface. Drilled and tapped hole must be 90° to load (work piece) surface

WARNING:

- Loads may slip or fall if proper Hoist Ring assembly and lifting procedures are not used.

- A falling load may cause serious injury or death.

- Use only genuine Crosby parts as replacements.

- Read, understand and follow all instructions, diagrams and chart information before using swivel hoist ring assembly.

Warnings and Application Instructions

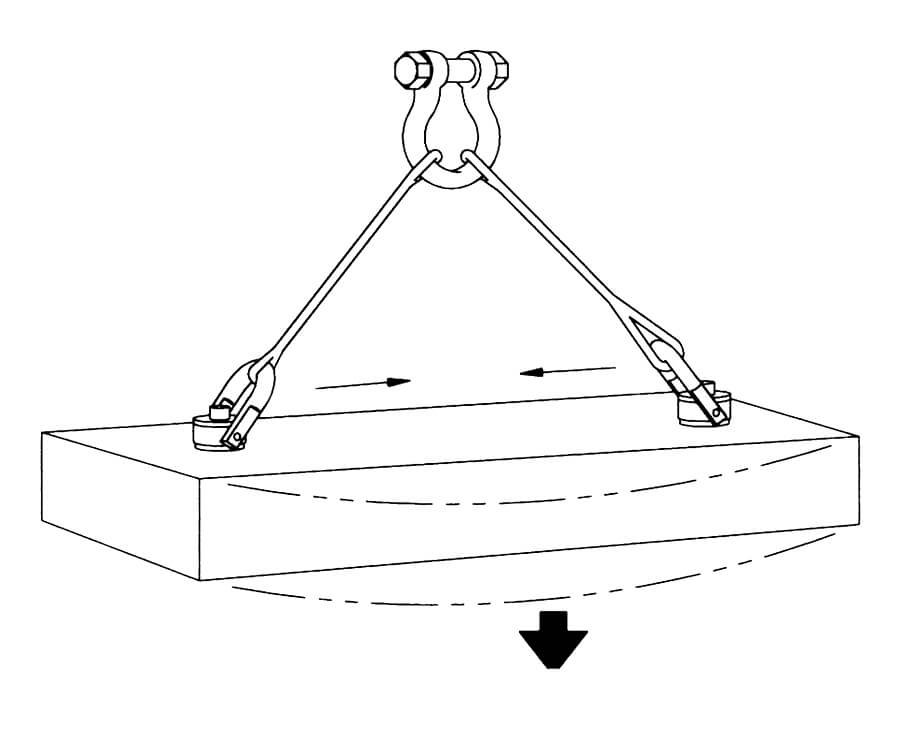

Do not reeve slings from one bail to another. This will alter the load and

angle of loading on the hoist ring.

WRONG

After slings have been properly attached to the hoist ring, apply force slowly. Watch the load and be prepared to stop applying force if the load starts buckling.

Buckling may occur if the load is not stiff enough to resist the compressive forces which result from the angular loading.

Operating Safety

- Never exceed the capacity of the swivel hoist ring, see Table 1 for UNC threads and Table 2 for Metric threads.

- When using lifting slings of two or more legs, make sure the forces in the legs are calculated using the angle from the vertical to the leg and select the proper size swivel hoist ring to allow for the angular forces.

(Note: Sling angles will de-rate sling members (chain, rope, or webbing) but will not de-rate swivel hoist ring capacity.)

Dependability In Lifting–

Everywhere, Every Time.

You’re in a tough lifting situation. Valuable equipment and the lives of your workers are on the line. You have to meet deadlines, observe regulations and stay within a budget. The slightest overlooked detail can

put employees and valuable equipment in harm’s way. Are you sure you have every detail covered?

When you’re taking on the weight of the world, turn to CERTEX, the lifting experts, for the experience and resources to make your most complex lifting challenge like just another day at the office.

CERTEX puts its world-wide network into the hands of local companies who know your needs and are close at hand to serve you.

put employees and valuable equipment in harm’s way. Are you sure you have every detail covered?

When you’re taking on the weight of the world, turn to CERTEX, the lifting experts, for the experience and resources to make your most complex lifting challenge like just another day at the office.

CERTEX puts its world-wide network into the hands of local companies who know your needs and are close at hand to serve you.

WARNING:

- Loads may slip or fall if proper Hoist Ring assembly and lifting procedures are not used.

- A falling load may cause serious injury or death.

- Use only genuine Crosby parts as replacements.

- Read, understand and follow all instructions, diagrams and chart information before using swivel hoist ring assembly.